Ancient Syrians favoured local obsidian

An archaeologist at the University of Sheffield has found evidence that, contrary to a widely held theory, ancient Syrians made their stone tools locally instead of importing finished tools from Turkey.

|

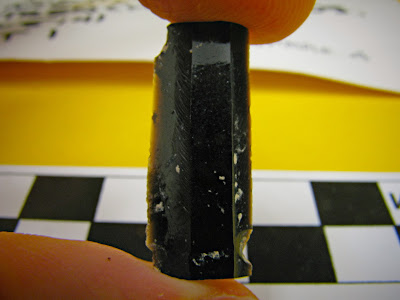

| Obsidian [Credit: Dr Ellery Frahm] |

The discovery, newly published online in Journal of Archaeological Science, has implications for our understanding of how early cities developed in these regions and how the geographic origins of raw materials affect developing states.

During the Early Bronze Age, around 5300 to 3100 years ago, blades made of chert and obsidian remained important despite the advent of metal tools. Much sharper than bronze tools, the stone blades were used for various cutting and scraping purposes, including agricultural activities, food processing, and crafts such as pottery and textile production.

Dr Ellery Frahm from the University's Department of Archaeology explained: "There is a prevalent idea that these blades were not made locally in Northern Mesopotamia, what is now Syria. It has been widely claimed that the blades were made in specialised workshops in southeast Turkey and then exported to villages and early cities throughout what is now Turkey, Syria, and Iraq."

However, Dr Frahm studied the origins of obsidian tools from various archaeological sites, including Tell Mozan where he has excavated, and showed that their raw materials originated from a variety of geological sources across Turkey, not merely those nearest the proposed workshop sites.

Dr Frahm continued: "This diversity of raw-material sources is inconsistent with export from highly specialised workshops in just one area of Turkey. Some of the artefacts' geological sources were hundreds of kilometres from the supposed blade workshops.

"The diverse obsidian origins, when combined with stone tool debris from the sites, suggests local production. Rather than arriving at the cities as finished blades, obsidian instead arrived as chunks, what are known as cores or preforms, and were brought by visitors either from diverse regions or with diverse itineraries. Instead of distant 'industrial' manufacturing, the materials for the blades reached the hands of the cities' specialists involved in household production principally for the local market."

Dr Frahm likens the situation to modern-day Syria: "Domestic manufacturing has been protected from competition by imports. Unlike its neighbour Jordan, there are no McDonalds or Starbucks, and until recently, Pepsi, Coca-Cola, and other international companies were banned from Syria.

"When our team headed into town for supplies, the shops had locally produced goods. The chemist had locally made pharmaceuticals and personal care products, while the market had local food and drink, paper products, even batteries. The beer was local too, brewed in Damascus and Aleppo."

This study of millennia-old stone tools also relates to contemporary issues of manufacturing and the uneven geographic distribution of raw-material resources around the world.

"The choice of which raw-material sources to use in manufacturing can have broad societal effects," explained Frahm. "Consider the rare earth elements, or REEs, crucial for electronics manufacturing. Your mobile phone and its battery, for example, depend on REEs to function. Until the 1980s, mines in California were the leading producers of REEs.

"Today, however, China supplies 90 percent of the REEs used in manufacturing despite only controlling one quarter of the world's supply. This is due, in part, to Chinese mines using extraction methods banned in the US. China has repeatedly reduced REE exports by as much as 30 percent per year. As a result, manufacturers dependent on these supplies have had to relocate their factories to China, and it is more profitable for China to export finished products instead of raw materials. This, in turn, has led to a range of geo-political consequences, such as recent American surveys for REEs in Afghanistan."

Dr Frahm sees parallels between REEs for electronics and obsidian for stone blades. The residents of ancient Syrian cities, he notes, imported raw materials like obsidian and locally produced the tools, rather than importing finished objects from distant workshops. He explained: "Knowing where these stone blades were produced allows us to start answering questions regarding the social relations linked to their production and distribution.

"Was there large-scale production under government control, or were the blades made by entrepreneurs working out of their homes? Who had the skills to made the blades, and where did they live and work? There were also effects on activities linked to these blades. Was agricultural output dependent on shipments of tools made by distant labourers, or were the tools made by the farmers themselves during the off season?"

Dr Frahm concluded: "Archaeological research can demonstrate that there are broad societal effects due to our choices regarding which raw-material sources to use and where our goods are produced."

Source: University of Sheffield [16-10-2013]

Elérhetőség

www.gazdtort.com

PTE BTK TTI Ókortörténeti TanszékH-7624 Pécs, Rókus u. 2.

+36-72-503600-23522